Group:Fabrication for Care

Actuators are something that control or move things around in a system, for e.g. by actuating a valve we mean to open and close it as per our need. An actuator is requires an energy source and a control signal which can be in the form of an electric or even mechanical signal.Actuators range from hydraulic, pneumatic to even thermal/ magnetic actuators but in this blog we’ll only be talking about electrical actuators i.e. motors.

source:https://www.google.com/search?q=actuators+and+sensors&source=lnms&tbm=isch&sa=X&ved=0ahUKEwiu5ZOzpabgAhXObVAKHWeJCsAQ_AUIDygC&biw=1280&bih=588#imgrc=8YlJX0vQemmIbM:

Sensors are the ones that that detect the changes in a system and send the information to a computer processor (usually a microcontroller). Sensors are used in everyday life like touch sensors in your phone to smoke detectors in our homes, we are completely surrounded by sensors.

source:https://medium.com/@ariesiitr/actuators-and-sensors-246eef0badd9

In a heating circuit you have the actual conductive wires (heat pad, heat surface) and the electronics. The heat pad has properties that the electronics has to take care of, like total resistance. So the electronics used is depending on your heating pad design.The most important property of the heating circuit is the total resistance of the heating wire (or network, surface).

Conductive materials:

We need a circuit, so we need conductive material. This must give of energy, the heath, so it has to have resistance. We have conductive thread and conductive fabrics. All conductive materials have different properties, some have nearly no resistance (copper and silver – that is good for some but bad for us.)

Low resistance materials: low = for your total heating wire pad around 5 Ohm.

Middle resistance: middle is resulting in 20-50 Ohm for your total heating wire.

High resistance, like K Ohm’s, this material is not vey useful for heating pad’s.

source:https://www.google.com/search?q=building+heat+controlling+circuit&source=lnms&tbm=isch&sa=X&ved=0ahUKEwihotnpqabgAhWMZVAKHWpiDtwQ_AUIDigB&biw=1280&bih=588#imgrc=fv3W2KGpbjRmuM:

The best total resistance of the total heating network to aim for is 6-10 Ohm, making a current of 500-1000 mA using 5 V. (This means for a short single wire you use a different conductive material as for a bigger surface or a very long wire.) some values of resistance of conductive thread for 30 cm of length: (values are not exact since my multimeter is a cheapo.)

So low resistance wires are used for single lines of heating, the somewhat higher resistance conductive wires are used in networks of wires, (heating pad’s), where you want to heat a surface. Depending on the length or the total surface (e.g. conductive fabrics) you choose for the conductive material giving the right total resistance. Then depending on the total resistance you can lower or raise the Voltage used. You can sew conductive thread on fabric, or knit conductive thread with a knitting machine, use it into woven materials.

source:http://etextile-summercamp.org/2013/?p=540

What is a Pressure Sensor?A pressure sensor is a device which senses pressure and converts it into an analog electric signal whose magnitude depends upon the pressure applied. Since they convert pressure into an electrical signal, they are also termed as pressure transducers.

https://www.google.com/search?biw=1280&bih=588&tbm=isch&sa=1&ei=IW5aXOWZH4PRwAKF3bbIAw&q=air+pressure+sensors+&oq=air+pressure+sensors+&gs_l=img.3..35i39j0i30.4296.5009..5798...0.0..0.199.584.1j3......1....1..gws-wiz-img.qdTO5G--YJI#imgrc=DrFNohuRpPv9eM:

Since a long time, pressure sensors have been widely used in fields like automobile, manufacturing, aviation, bio medical measurements, air conditioning, hydraulic measurements etc.

source:https://www.engineersgarage.com/articles/pressure-sensors-types-working

Air pressure sensor is a system in which is working by measuring the high performance capacity pressure sensor,using conditioning chip,wire connecting in electronic board,which on the other hand pump and make air into material.

Our group from Fabrication4Care walk through learning basic things,in order to be able to develop of own prototype of a project.Since we decide with our collegues and teachers to make a group work,we start considering which kind of project we will present for our Interdisciplinary project.The aim of each team was to invent a project which could help the people with different disabilities and how this will have a contribution to the world itself.

Each part of our group of Fabrication for Care was pleased to introduce their final project ideas,by making a Powerpoint Presentation in front of audience,consit of the techers and some companies.Our group is consit of two people,me and my collegue decide teh idea of our project to be a compression socks with an inflatable extension.

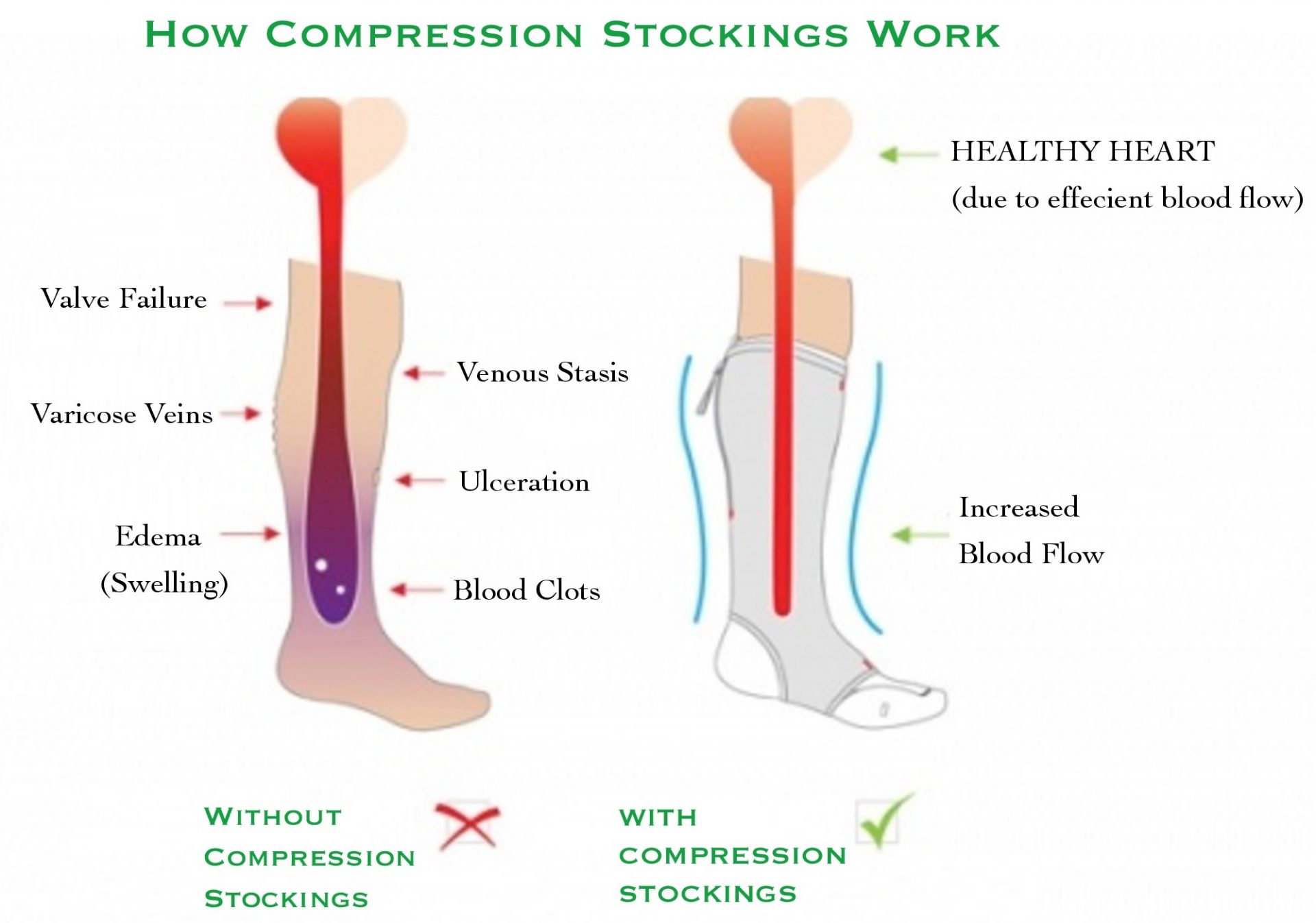

Our idea was inspired by our fathers who had a problem with the veins,caused by the unproper circulation of the blood pressure.In addition,by doing a research we figure out that this compression socks are existing and how they actually work.

Compression stockings are tightest at the ankles and gradually become less constrictive toward the knees and thighs. By compressing the surface veins, arteries and muscles, they force circulating blood through narrower channels. As a result, the arterial pressure is increased, which causes more blood to return to the heart and less blood to pool in the feet.

source:https://www.google.com/search?q=compression+stockings%5C&source=lnms&tbm=isch&sa=X&ved=0ahUKEwj_ruOCuabgAhXDZ1AKHX-kCyUQ_AUIDygC&biw=1280&bih=588#imgrc=e61Dgu7Lf22oiM:

Our purpose is to use a compression sock,combined with an inflatable,which will work like an additional support, making the healing faster and more efficient,by connecting the pumping of the inflatable via walking or pressing the leg.